Manufacturing Excellence for Healthcare Innovation.

Helping OEMs and Inventors to scale their businesses by partnering with a flexible medical device contract manufacturer.

Want to find out more?

Partnering for the long term.

Over 50% of customers have partnered with us for more than 10 years making Europlaz one of the most respected medical device contract manufacturers in the UK.

Overcoming your challenges.

The Europlaz approach begins by understanding our customers individual needs, focussing on manufacturing opportunities and challenges.

We understand one size does not fit all, so we offer tailored solutions, allowing us to effectively collaborate with customers to ensure efficiency and effectiveness when it comes to medical device development and commercialisation.

Europlaz supports customers to improve lead times, costs, quality, regulatory approval, or supply chain management.

Focus on your core strengths and business objectives; trust Europlaz to be the manufacturing extension of your team.

Areas of expertise.

Specialising in the end-to-end manufacturing of medical devices. Capabilities include everything from initial design for manufacturing to full-scale production and packaging, ensuring a seamless transition from concept to market-ready products.

Want to find out more?

Solutions for all OEMs.

At Europlaz, we take pride in our innovative and responsive approach to commercial partnerships. With over 40 years of experience in medical device manufacturing and product innovation, we offer a wealth of expertise to OEMS.

Applications & industries.

At Europlaz, we pride ourselves on being at the forefront of medical device development. With a legacy of supporting projects across multiple medical industries and an agile, personable team; we bring a full complement of experts dedicated to advancing the medical field in the following sectors:

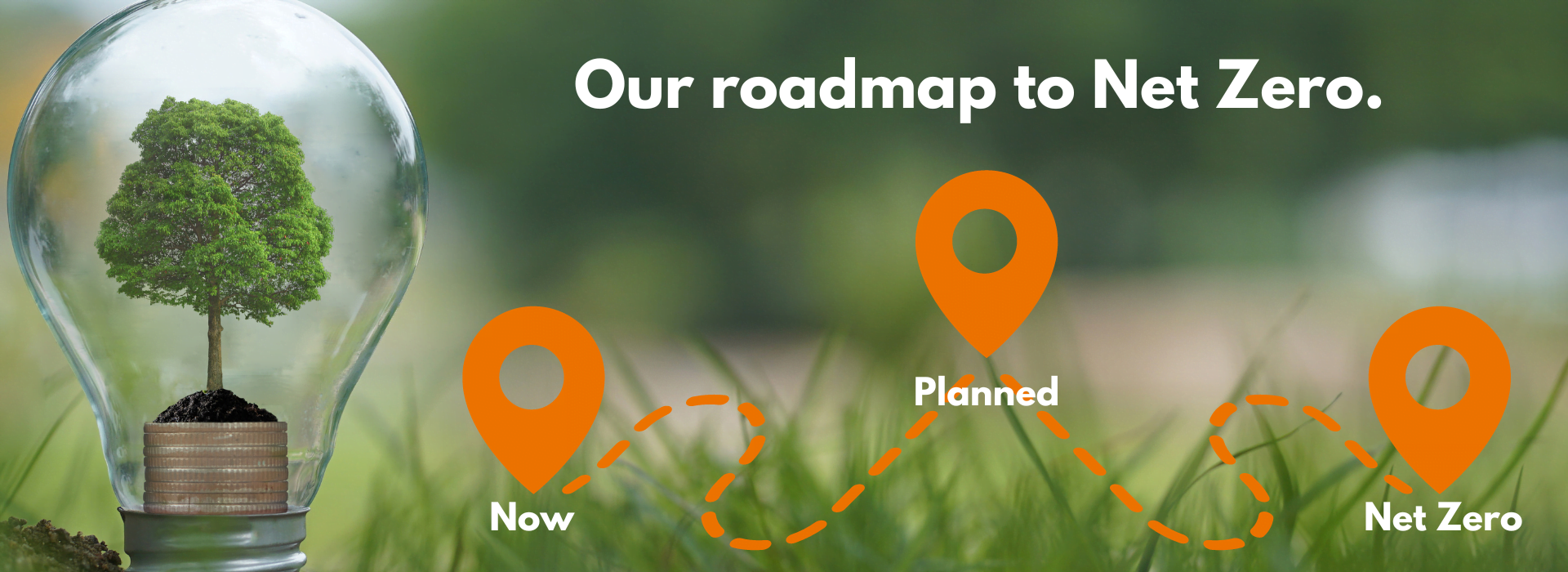

Years 1 to 5 (2020 to 2025)

Key focus areas:

- Renewable energy

- Employee engagement and training

- Sustainable procurement

Our progress so far:

- Installed over 800 solar panels

- Changed electric supplier to a renewable source

- Installed electric car chargers on site for our employees

- Replaced old injection moulding machines with fully electric energy efficient replacements

- Integrated sustainability into the procurement process

What we intend to achieve

- Getting our ISO 14001 Certification

- Complete waste management training for all employees

- Get all our suppliers signed up to our Supplier code of conduct

Years 5 to 10 (2025 to 2030)

Key focus areas

- Energy efficiency

- Product sustainability

- Continued employee engagement

What we intend to achieve

- Expand our solar panels

- Aim for all company vehicles to be electric

- Complete life cycle assessments on our product lines

- Calculate our entire scope 3

- Explore feasibility of other renewable energy opportunities

Years 10 to 20 (2030 to 2045)

Key focus areas

- Eliminating Scope 1

- Carbon offsetting

What we intend to achieve

- Continuing to be more efficient

- Lowering our scope 3 emissions

- Carbon offsetting where needed

Blog.

Lets take the first step.

So that we can understand your needs and challenges, we’d welcome the opportunity to have a quick chat. Simply fill in this short form and we’ll be in contact.